American Wire Gauge Conductor Size Table

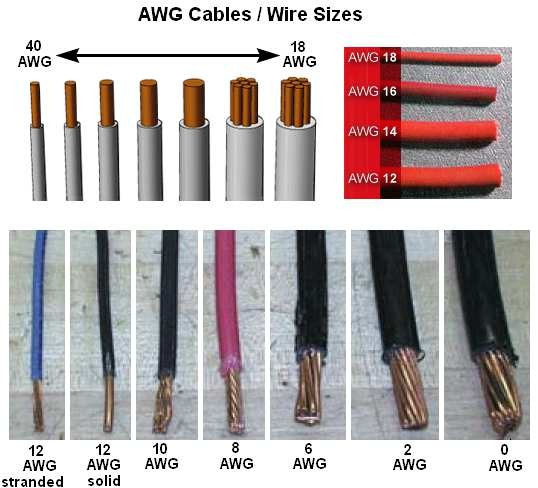

American wire gauge (AWG) is a standardized wire gauge system for the diameters of round, solid, nonferrous, electrically conducting wire. The larger the AWG number or wire guage, the smaller the physical size of the wire. The smallest AWG size is 40 and the largest is 0000 (4/0). AWG general rules of thumb - for every 6 gauge decrease, the wire diameter doubles and for every 3 gauge decrease, the cross sectional area doubles. Note - W&M Wire Gauge, US Steel Wire Gauge and Music Wire Gauge are different systems.

American Wire Gauge (AWG) Sizes and Properties Chart / Table

Table 1 lists the AWG sizes for electrical cables / conductors. In addition to wire size, the table provides values load (current) carrying capacity, resistance and skin effects. The resistances and skin depth noted are for copper conductors. A detailed description of each conductor property is described below Table 1.

| AWG |

Diameter

[inches] |

Diameter

[mm] |

Area

[mm2] |

Resistance

[Ohms / 1000 ft] |

Resistance

[Ohms / km] |

Max Current

[Amperes] |

Max Frequency

for 100% skin depth |

| 0000 (4/0) |

0.46 |

11.684 |

107 |

0.049 |

0.16072 |

302 |

125 Hz |

| 000 (3/0) |

0.4096 |

10.40384 |

85 |

0.0618 |

0.202704 |

239 |

160 Hz |

| 00 (2/0) |

0.3648 |

9.26592 |

67.4 |

0.0779 |

0.255512 |

190 |

200 Hz |

| 0 (1/0) |

0.3249 |

8.25246 |

53.5 |

0.0983 |

0.322424 |

150 |

250 Hz |

| 1 |

0.2893 |

7.34822 |

42.4 |

0.1239 |

0.406392 |

119 |

325 Hz |

| 2 |

0.2576 |

6.54304 |

33.6 |

0.1563 |

0.512664 |

94 |

410 Hz |

| 3 |

0.2294 |

5.82676 |

26.7 |

0.197 |

0.64616 |

75 |

500 Hz |

| 4 |

0.2043 |

5.18922 |

21.2 |

0.2485 |

0.81508 |

60 |

650 Hz |

| 5 |

0.1819 |

4.62026 |

16.8 |

0.3133 |

1.027624 |

47 |

810 Hz |

| 6 |

0.162 |

4.1148 |

13.3 |

0.3951 |

1.295928 |

37 |

1100 Hz |

| 7 |

0.1443 |

3.66522 |

10.5 |

0.4982 |

1.634096 |

30 |

1300 Hz |

| 8 |

0.1285 |

3.2639 |

8.37 |

0.6282 |

2.060496 |

24 |

1650 Hz |

| 9 |

0.1144 |

2.90576 |

6.63 |

0.7921 |

2.598088 |

19 |

2050 Hz |

| 10 |

0.1019 |

2.58826 |

5.26 |

0.9989 |

3.276392 |

15 |

2600 Hz |

| 11 |

0.0907 |

2.30378 |

4.17 |

1.26 |

4.1328 |

12 |

3200 Hz |

| 12 |

0.0808 |

2.05232 |

3.31 |

1.588 |

5.20864 |

9.3 |

4150 Hz |

| 13 |

0.072 |

1.8288 |

2.62 |

2.003 |

6.56984 |

7.4 |

5300 Hz |

| 14 |

0.0641 |

1.62814 |

2.08 |

2.525 |

8.282 |

5.9 |

6700 Hz |

| 15 |

0.0571 |

1.45034 |

1.65 |

3.184 |

10.44352 |

4.7 |

8250 Hz |

| 16 |

0.0508 |

1.29032 |

1.31 |

4.016 |

13.17248 |

3.7 |

11 k Hz |

| 17 |

0.0453 |

1.15062 |

1.04 |

5.064 |

16.60992 |

2.9 |

13 k Hz |

| 18 |

0.0403 |

1.02362 |

0.823 |

6.385 |

20.9428 |

2.3 |

17 kHz |

| 19 |

0.0359 |

0.91186 |

0.653 |

8.051 |

26.40728 |

1.8 |

21 kHz |

| 20 |

0.032 |

0.8128 |

0.518 |

10.15 |

33.292 |

1.5 |

27 kHz |

| 21 |

0.0285 |

0.7239 |

0.41 |

12.8 |

41.984 |

1.2 |

33 kHz |

| 22 |

0.0254 |

0.64516 |

0.326 |

16.14 |

52.9392 |

0.92 |

42 kHz |

| 23 |

0.0226 |

0.57404 |

0.258 |

20.36 |

66.7808 |

0.729 |

53 kHz |

| 24 |

0.0201 |

0.51054 |

0.205 |

25.67 |

84.1976 |

0.577 |

68 kHz |

| 25 |

0.0179 |

0.45466 |

0.162 |

32.37 |

106.1736 |

0.457 |

85 kHz |

| 26 |

0.0159 |

0.40386 |

0.129 |

40.81 |

133.8568 |

0.361 |

107 kHz |

| 27 |

0.0142 |

0.36068 |

0.102 |

51.47 |

168.8216 |

0.288 |

130 kHz |

| AWG |

Diameter

[inches] |

Diameter

[mm] |

Area

[mm2] |

Resistance

[Ohms / 1000 ft] |

Resistance

[Ohms / km] |

Max Current

[Amperes] |

Max Frequency

for 100% skin depth |

| 28 |

0.0126 |

0.32004 |

0.081 |

64.9 |

212.872 |

0.226 |

170 kHz |

| 29 |

0.0113 |

0.28702 |

0.0642 |

81.83 |

268.4024 |

0.182 |

210 kHz |

| 30 |

0.01 |

0.254 |

0.0509 |

103.2 |

338.496 |

0.142 |

270 kHz |

| 31 |

0.0089 |

0.22606 |

0.0404 |

130.1 |

426.728 |

0.113 |

340 kHz |

| 32 |

0.008 |

0.2032 |

0.032 |

164.1 |

538.248 |

0.091 |

430 kHz |

| 33 |

0.0071 |

0.18034 |

0.0254 |

206.9 |

678.632 |

0.072 |

540 kHz |

| 34 |

0.0063 |

0.16002 |

0.0201 |

260.9 |

855.752 |

0.056 |

690 kHz |

| 35 |

0.0056 |

0.14224 |

0.016 |

329 |

1079.12 |

0.044 |

870 kHz |

| 36 |

0.005 |

0.127 |

0.0127 |

414.8 |

1360 |

0.035 |

1100 kHz |

| 37 |

0.0045 |

0.1143 |

0.01 |

523.1 |

1715 |

0.0289 |

1350 kHz |

| 38 |

0.004 |

0.1016 |

0.00797 |

659.6 |

2163 |

0.0228 |

1750 kHz |

| 39 |

0.0035 |

0.0889 |

0.00632 |

831.8 |

2728 |

0.0175 |

2250 kHz |

| 40 |

0.0031 |

0.07874 |

0.00501 |

1049 |

3440 |

0.0137 |

2900 kHz |

Table 1: American Wire Gauge (AWG) Cable / Conductor Sizes and Properties

AWG Notes: American Wire Gauge (AWG) is a standardized wire gauge system used predominantly in the United States to note the diameter of electrically conducting wire. The general rule of thumb is for every 6 gauge decrease the wire diameter doubles and every 3 gauge decrease doubles the cross sectional area.

Diameter Notes: A mil is a unit of length equal to 0.001 inch (a "milli-inch" or a "thousandth of one inch") ie. 1 mil = 0.001".

Resistance Notes: The resistance noted in the table above is for copper wire conductor. For a given current, you can use the noted resistance and apply Ohms Law to calculate the voltage drop across the conductor.

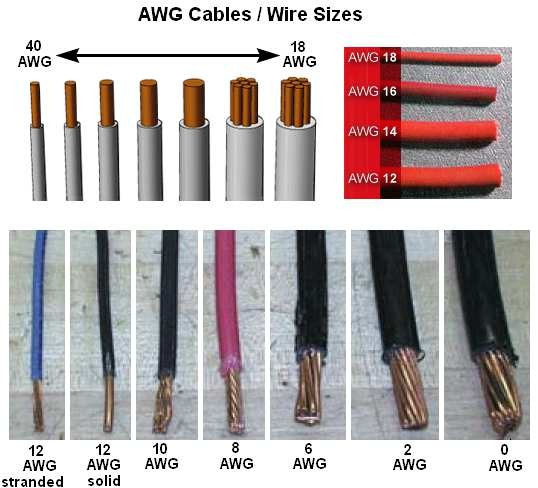

Current (ampacity) Notes: The current ratings shown in the table are for power transmission and have been determined using the rule of 1 amp per 700 circular mils, which is a very conservative rating. For reference, the National Electrical Code (NEC) notes the following ampacity for copper wire at 30 Celsius:

14 AWG - maximum of 20 Amps in free air, maximum of 15 Amps as part of a 3 conductor cable; 12 AWG - maximum of 25 Amps in free air, maximum of 20 Amps as part of a 3 conductor cable; 10 AWG - maximum of 40 Amps in free air, maximum of 30 Amps as part of a 3 conductor cable.

Check your local electrical code for the correct current capacity (ampacity) for mains and in wall wiring.

Skin Effect and Skin Depth Notes: Skin effect is the tendency of an alternating electric current (AC) to distribute itself within a conductor so that the current density near the surface of the conductor is greater than that at its core. That is, the electric current tends to flow at the "skin" of the conductor. The skin effect causes the effective resistance of the conductor to increase with the frequency of the current. The maximum frequency show is for 100% skin depth (ie. no skin effects).

How to Convert From Copper to Aluminum Conductors

Ampacities based upon Table 310-16 of the National Electrical Code.

A commonly used rule-of-thumb for converting the two conductor metals is to have aluminum two AWG sizes larger than copper for equivalency. This works in most cases when one is working inside the American Wire Gage system. One example where the two AWG size rule may not be appropriate is for a 90 ampere circuit which could be served with 75°„C rated cond uctors (provided equipment is so marked). From NEC Table 310-16, the selection could be a No. 3 AWG copper or No. 2 aluminum conductor provided voltage drop is not a factor. Also, with conductor sizes 250 kcmil and larger we are no longer in the American Wire Gage system; therefore, the two AWG size rule can no longer apply.

The technically correct way to make these conversions is to select an equivalent or higher ampacity rating while maintaining the same conductor temperature rating. For example, replace a No. 6 AWG, copper, type TW conductor with an aluminum conductor. Table 310- 16 lists the ampacity of No. 6 copper TW (60°„C colu mn) at 55 amperes. Now select an aluminum conductor from the 60°„C column that has an ampacity of 55 amperes or higher. A No. 4 aluminum would be used to replace the No. 6 copper TW conductor. This aluminum

conductor does not have to be type TW, it could have a higher temperature designation such as THW or THHN; however, the ampacity must be based upon a 60°„C rated conductor.

Notice that a No. 6 aluminum type THHN conductor has an ampacity rating of 60 amperes which is higher than the 55 ampere rating for No. 6 copper TW. It may seem logical that No. 6 aluminum THHN could replace No. 6 copper TW based upon the ampacity rating alone; however, it is not correct. Difference in voltage drop is one consideration opposing a size-for-size replacement but the main reason lies with equipment ratings. A conductor must terminate at the equipment it serves and this equipment is tested and listed with definite conductor types. Equipment rated 100 amperes or less is tested and listed for use with 60°„C rated cond uctors unless marked otherwise and to connect a conductor to be used at 90°„C ampac ity effectively voids the listing. It would also violate section 110-3 (b) of the NEC because this section states that equipment shall be installed according to any instructions in the listing or labeling. To repeat, always make conversions from aluminum to copper or copper to aluminium by selecting equivalent or large ampacity while maintaining the same conductor temperature rating.

American Wire Guage (AWG) Wire Sizes