Now, there is a better way, which enables control panels to be wired more quickly, more easily, and with much less risk of errors

Traditional cabinet wiring operations are cumbersome, labor-intensive, and prone to errors. Most control panels are still wired simply by referring to a schematic diagram, but this process is time-consuming and requires a high level of expertise. Wiring a panel is one of the most skilled jobs in the panel building industry. The person wiring the panel must decide on the precise routing of the wires, ensure certain wires are segregated where necessary, and keep track of the progress of the wiring. This process is very time-consuming and requires a great deal of skill.

To achieve this, Eastontech offer two solutions to choose from. With fully automatic wire harnessing, production processes are modernized and made significantly more efficient.

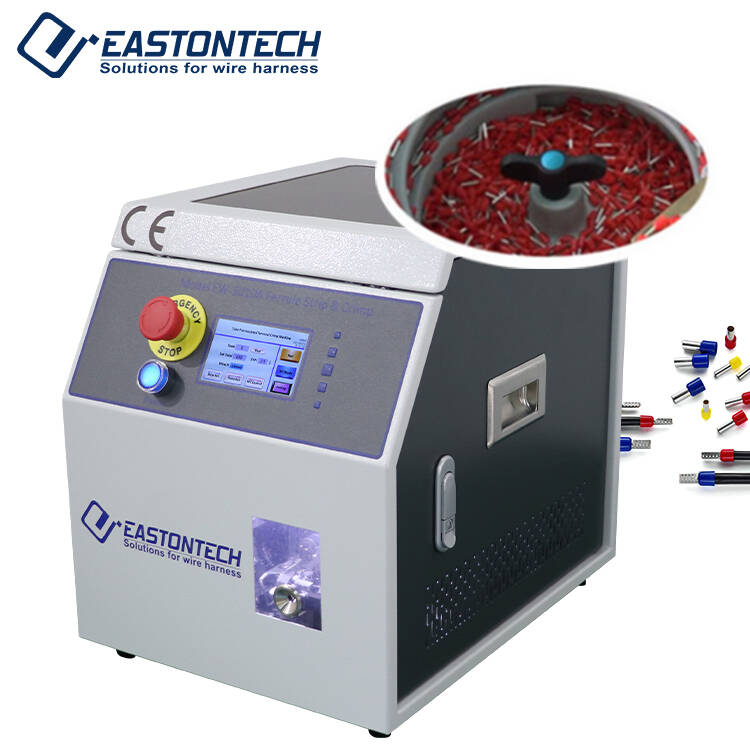

One option is our EW-8155 Fully Automatic Inserting Number Tube Wire Cut Strip Crimp Machine. With fully automatic wire harnessing, production processes are modernized and made significantly more efficient.

It can perform wire cutting, single-end stripping, double-end stripping, double-end crimping, double-end printing, and baking of marker tubes with precision and stable performance. It features an internal four-wheel synchronous wire feeder that consistently maintains wire tension, an automatic terminal tape cutting device, and a bilingual touch screen for parameter settings, making adjustments quick and operation simple.

Wiring a control cabinet no longer needs to be done by an expert. EW-8155 simplifies the wiring process so that anyone can do it!

EW-8155

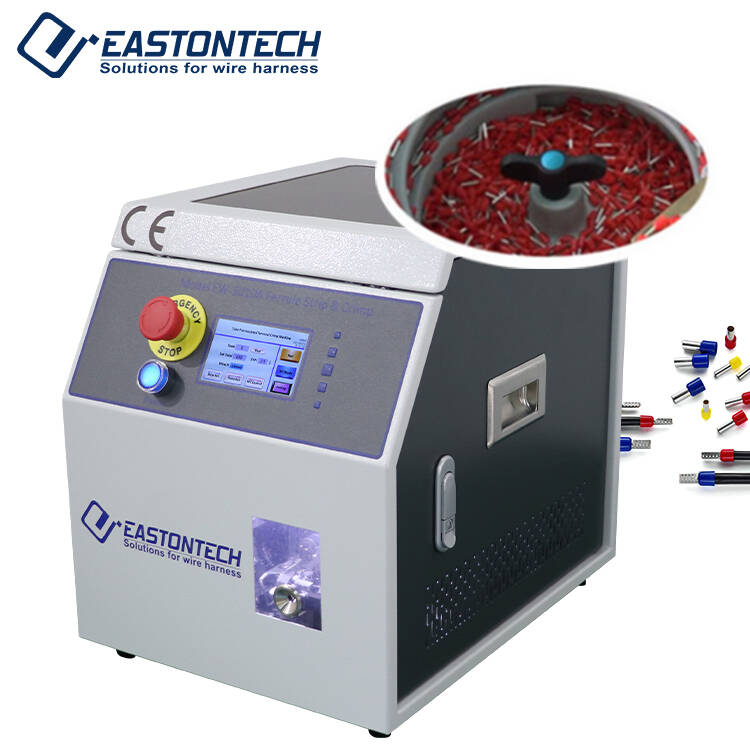

The other option is to use our semi-automatic machines to complete the above tasks. While the semi-automatic machines may result in some wastage of manpower and resources, and their stability, production speed, and precision are not as high as fully automatic machines, they are significantly more affordable.

This makes them an excellent choice for startups and smaller enterprises. Semi-automatic machines can adapt to a wider range of wire harness production needs, providing flexibility and cost-effectiveness for businesses that are just beginning to scale. Despite the trade-offs, the lower initial investment can be a strategic advantage for companies looking to optimize their budget while still improving their wiring processes.

EW-5010B

EW-3035+L

EW-1260

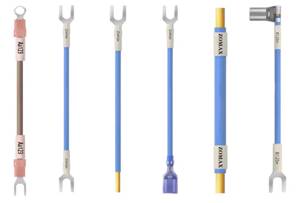

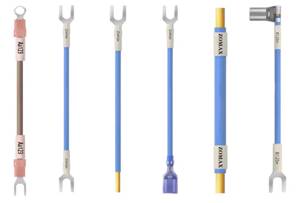

Through our company's pre-labeled cable solution, each cable is pre-labeled with a unique identifier. Installers can directly confirm the position of the cable through the label, greatly reducing wiring time and error rates. This method not only improves wiring efficiency but also reduces labor costs.

By adopting pre-labeled cable solution, you can make cabinet wiring smarter, enhancing the performance and management efficiency of your devices.