Home

+

Products

+

- Overview

- Cut

- Cut&Strip

- Strip,Twist

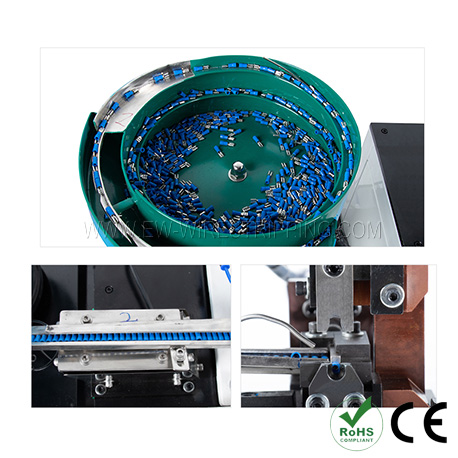

- Crimp

- Shield Process

- Cut Strip Terminate& Solder

- Labeling Machine

- Wind & Nylon Tying

- Cable Solder& Weld Machine

- Tape Bundling

- Prefeeding& Deposit System

- Plug Production

- Heat Shrinkage

- PVC Injection

- Copper Belt Press

- Tape Dispenser

- Printing Marking

- Wire Harness Tester

- Solar Cable Line

- Moulds&Accessory