1. EW-1295 is designed for cutting wide range of industrial materials.

2. Various tube, pipe, hose, fabric, paper, film, sheet, strip, band, foam, foil, wire, cable and rope are within the capability.

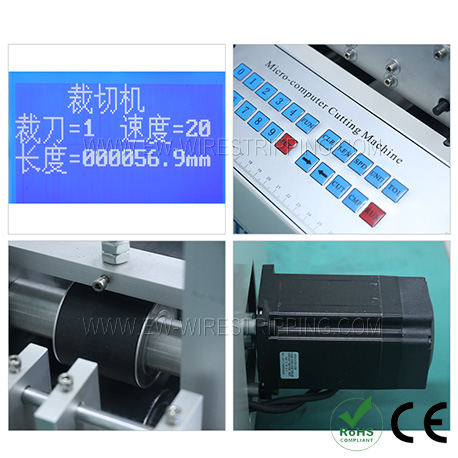

3. Mainboard with ARM Control System: fast operation speed (arithmetic speed), high efficiency, high integration level, large memory capacity and most steady performance.

4. Equipped with material roll hold bar and roll fixture to ensure the steady feeding and cutting process.

5. Equipped with 4 feeding rails. The gap between the rails can be adjusted according to the material width, which also allows maximum 3 production lines.

6. SKD-11 material is selected as the balde material, and the average lifetime is up to 18 months.

7. High definition LCD display with easy production setup: total quantity, batch quantity, batch delay, length calibration, reset etc.

8. Factory reset button to reset all the data.

9. Length calibration program to correct the cutting length.