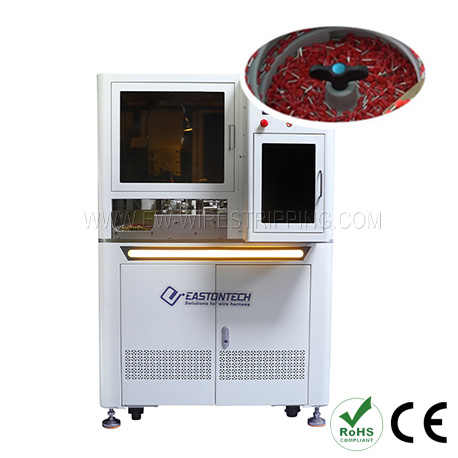

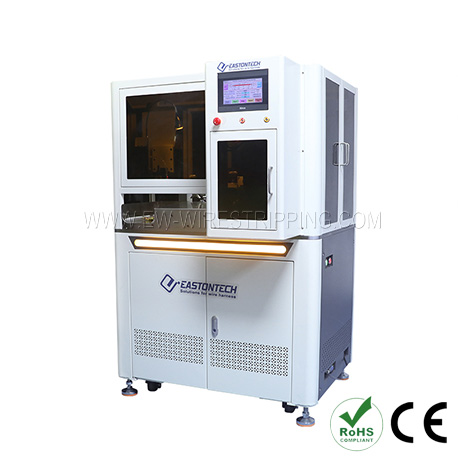

1. This series is double-side automatic crimping machine for bulk terminals. The terminals are automatically fed through the vibrating plate. This machine can cut the wire to a fixed length, strip and twist the wire at both ends, and crimp the terminal. For the closed terminal, the function of rotating and twisting the wire can also be added. Twist the copper wire and then insert it into the inner hole of the terminal for crimpinq, which can effectively prevent the reverse wire phenomenon.

2. The wire inlet is equipped with 3 sets of straighteners, which can automatically straighten the wire and improve the stability of the machine operation. Multiple sets of wire feeding wheels can jointly feed the wire to prevent the wire from slipping and improve the wire feeding accuracy. The terminal machine is integrally formed with nodular cast iron, the whole machine has strong rigidity and the crimping size is stable. The default crimping stroke is 30mm, and the standard OTP bayonet mold is used. ln addition, a model with a stroke of 40mm can also be customized, and various European molds can be used. lt can also be equipped with a terminal pressure monitor to monitor the pressure curve changes of each crimping process in real time, and automatically alarm and stop when the pressure is abnormal.