What is Crimping Force Monitor

Crimping Force Monitor (CFM) is a device that monitors the quality stability of the manufacturing process by detecting the crimp force in the crimping process of the crimping machine .

The principle is : first collect a certain number of good product waveform and generate a reference waveform . Then compare the waveform of production with the reference waveform .If the difference exceeds the preset threshold , the alarm signal is output to suspend the manufacturing process . The specific comparison method is to extract the eigenvalue(such as the peak and area of the specified interval ) in a specified interval and compare with the reference waveform . For the alarm wave forms , a manual confirmation is needed for product quality control . After choosing good or bad manually , the alarm state will be reset automatically and the manufacturing process can be continued .

What Can CFM Actually Detect:

There is a general assumption within the industry that crimp force monitoring will provide reliable detection of all general crimping errors during processing, including:

¡ñ Wrong strip length

¡ñ Missing strands

¡ñ Wrong wire cross section

¡ñ Wrong terminal

¡ñ Inconsistent terminal material

¡ñ Insulation in wire crimp

¡ñ Wrong insertion depth

¡ñ Wrong crimp height

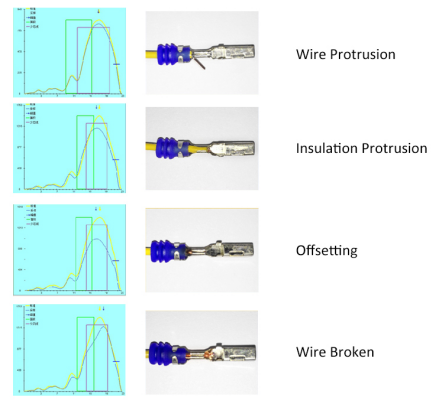

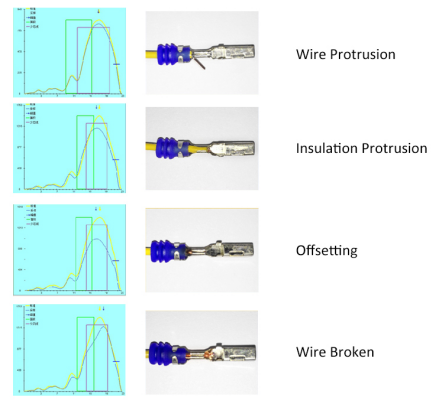

Wire Protrusion:

Alarm pressure wave forms tend to decrease throughout the waveform . However , the waveform is not severely tilted . The same waveform appears when the wire is broken .

Insulation Protrusion:

The insulating material protrudes into the terminal crimping portion and is crimped with the core wire , causing the wire to break. It can be clearly observed that the pressure drops sharply before reaching the peak .

Offsetting:

The degree of offsetting is measured by the distance between the front end f the core and the bell mouth crimped by the terminal . In this case, the offsetting is about 1mm . Although the pressure wave forms are similar, the overall waveform is reduced . As a result , all factors are below neglectable tolerance limit .

Wire Broken:

The insulating material protrudes into the terminal crimping portion and is crimped with the core wire , causing the wire to break . It can be clearly observed that the pressure drops sharply before reaching the peak.