Crimping Method of Wire

Harness Terminal and Shielding Ring

Abstract: Introduce two styles of terminals in

high-voltage wiring harnesses, as well as the characteristics and crimping

methods of each terminal. Introduce the crimping types of closed terminals and

shielding rings, analyze the characteristics of each terminal and shielding

ring crimping, and support the subsequent development of molds and jaw types,

and ultimately ensure that the product quality meets the requirements.

The automobile wiring harness terminal

is one of the main connecting parts in the wiring harness, which are connected

together after crimping the wire and the terminal, and play the role of

transmitting current and signal, and meet the normal use of the vehicle.

According to different terminal requirements, it can be divided into two

styles: open terminal and closed terminal. The open terminal mainly refers to

the traditional open terminal. Most of the terminals have a chain strap

structure to achieve uninterrupted and continuous crimping on the equipment. A

few large square terminals (greater than 8 square) are all single terminals,

and a single crimp is required for crimping . Enclosed terminals are also

called tube-type terminals. The terminals are all single terminals. When crimping,

the wire needs to be inserted into the crimping hole of the terminal and then

crimped.

With the development of new energy

vehicles, high-voltage wiring harnesses have gradually increased, and the main

form of their terminals is closed terminals. The open terminal is commonly used

in wiring harnesses, and the crimping method is relatively simple, so I won't

do more analysis here. Today, we will mainly analyze the crimping methods of

enclosed terminals and shielding rings in high-voltage wiring harnesses.

Shielding ring crimping is a unique type of crimping in high-voltage wiring

harnesses. It is mainly used for shielding connection. The function will not be

described in detail here. The main crimping methods of tube-type terminals are:

6-sided crimping; 6-sided 2 point crimping; MW type crimping; 4 point crimping.

Shielding ring crimping methods mainly include: 6-sided crimping; 6-sided

crimping with 2 points; 6-point crimping. Below we analyze from their crimping

methods.

1 Closed terminal

crimping

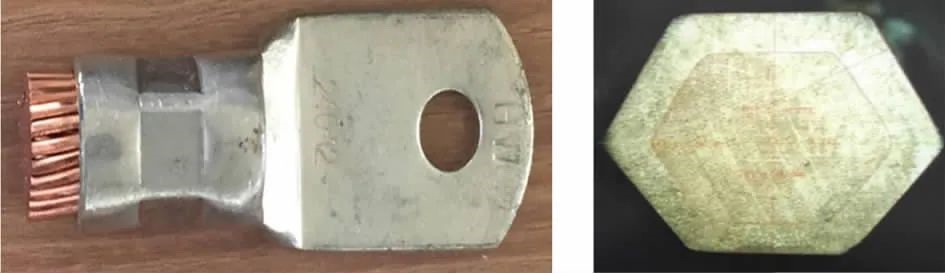

1) The 6-side crimping method of the

terminal.

The 6-side crimping of the terminal is

generally suitable for wires of more than 8 square meters. The wire and the

terminal square are completely matched for crimping. After crimping, the

terminal profile and pull-off force can be qualified. The crimping equipment

mainly uses hydraulic equipment to ensure soft crimping during the terminal

crimping process and avoid terminal cracks. In the sample line stage, most of

the six-sided hydraulic special equipment without changing the mold is used,

and the special hydraulic equipment is used according to the crimping method in

batches. The 6-side crimping diagram of the terminal is shown in Figure 1, and

the 6-side crimping cross-sectional view is shown in Figure 2.

Figure 1 6-side crimping diagram of the terminal

Figure 2 6-side crimping cross-section of the terminal

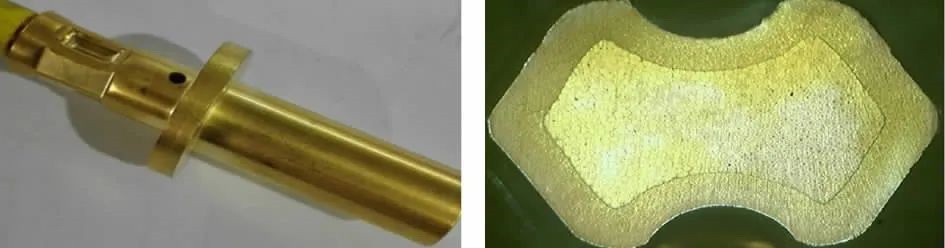

2) 6-sided 2-point crimping method.

6-sided

2-point crimping (6-square double-point crimping), generally suitable for wires

above 8 square, crimping when the wire and terminal fit is slightly smaller

than the terminal diameter. After crimping, the terminal profile and pull-off

force are also qualified. The crimping equipment mainly uses hydraulic

equipment. Generally, there are imported crimping equipment and domestic

crimping equipment, which can meet the crimping quality, but the stability of

imported equipment is better. Since the country has not issued a formal

standard for high-voltage wiring harnesses, the crimping method has not yet

been completely unified, and the 6-sided 2-point crimping method is often used.

The 2-point crimping diagram on the 6 sides of the terminal is shown in Figure

3, and the cross-sectional view of the 2-point crimping on the 6 sides of the

terminal is shown in Figure 4.

Figure 3 6-sided 2-point crimping diagram of the terminal

Figure 4 6-sided

2-point crimping cross-section of the terminal

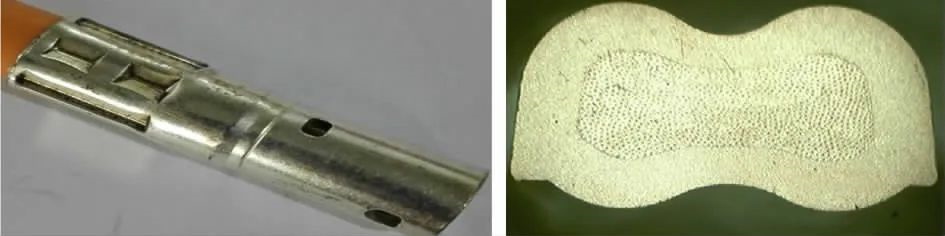

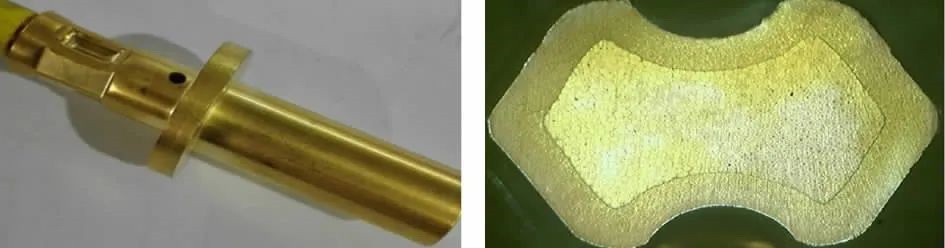

3) MW type crimping method.

MW type crimping is generally suitable for wires of

more than 8 square meters, and the wire and terminal are slightly smaller than

the diameter of the terminal for crimping. However, in order to ensure the

deformation of the terminal crimping part and the good contact and coordination

of the wire, the MW type crimping can be preferred, and the terminal profile

and pull-out force after crimping are also qualified. New energy vehicles are

increasing day by day, and the crimping stability is gradually increasing. MW

crimping is a superior crimping method based on 6-sided 2-point crimping. It is

worthwhile from terminal deformation to profile effect analysis. Popular

crimping method. The patent for this crimping method has been accepted. MW type

crimping is shown in Figure 5, and MW type crimping section is shown in Figure

6.

Figure 5 MW type crimping diagram Figure 6 MW type crimping

section view

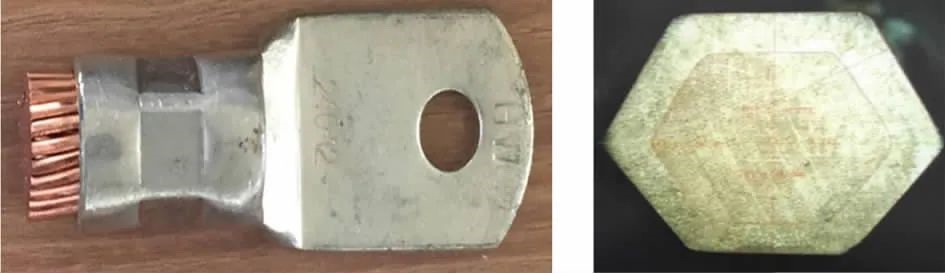

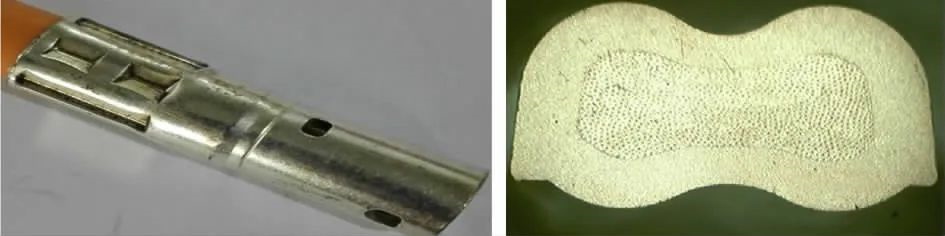

4) 4-point crimping method.

4-point crimping (square crimping or quadrilateral double

crimping), generally suitable for wires below 6 square, crimping when the wires

and terminals are well matched, and the terminal profile and pull-off force are

also qualified after crimping. The squares of wires commonly used in 4-point

crimping are 3 squares, 4 squares, and 6 squares. Among them, there are more

than 3 square wires and 4 square wires. During the crimping process, it is

necessary to pass the wire into the terminal crimping hole first, and then hold

the wire and the terminal for crimping. During the crimping process, prevent

the terminal from coming off, which affects the operation efficiency. The

4-point crimping and cross-section are shown in Figure 7 and Figure 8.

Figure 7 4-point crimping diagram Figure 8 4-point

crimping cross-section

2 Shielding ring crimping method

1) 6-side crimping method.

The shielding ring is crimped on 6 sides, generally

suitable for wires of more than 3 square meters. It is a crimping method with a

good match between the wire shielding net and the shielding ring, and the

pull-off force after crimping is qualified. Under normal circumstances, when

the shielding ring and the shielding net and the wire have a small gap and a

close fit, this type of crimping method is widely used, and it is one of the

commonly used shielding ring crimping methods. The 6-side crimping diagram of

the shielding ring is shown in Figure 9.

Figure 9

2) 6-sided 2-point crimping method.

The shielding ring is crimped at 2 points on 6 sides. It is

generally suitable for crimping with the shielding net of 8 square wires or

more and the shielding ring. The pull-off force after crimping is qualified.

Normally, when the shielding ring, shielding net and wire gap is slightly

larger, this crimping method is adopted. The number of crimping points is

determined according to the length and size of the shielding ring. It is also

one of the commonly used shielding ring crimping methods. The patent for this

crimping method has been accepted. Figure 10 shows the 2-point crimping diagram

of the shielding ring on the 6 sides.-side crimping diagram of shielding ring

Figure 10 Shielding ring 6-sided 2-point crimping diagram

3) 6-point crimping method.

The shielding ring is crimped at 6 points, which is

generally suitable for the crimping method of the 10-square wire shielding net

and the shielding ring. After crimping, the pull-off force is qualified.

Generally, when the gap between the shielding ring and the shielding net and

the wire is large, this crimping method is used. The main reason for using this

method is that the shielding ring of the connector and the wire do not match,

and the toughness of the material of the shielding ring is required. Otherwise,

cracks will occur after the shielding ring is crimped with the wire, and the

quality of the shielding ring will be cracked, resulting in poor product

quality. Qualified, unable to meet production needs. The patent for this

crimping method has been accepted. The 6-point crimping diagram of the shield

ring is shown in Figure 11.

Figure 11 6-point crimping diagram of shield ring

3 Summary

In

the actual production process of high-voltage wiring harness, crimping is rated

as a key feature, and the wiring harness manufacturing process is one of the

important production links. In the process of developing the crimping mold, the

crimping engineer must carefully analyze the matching of the connector

structure and the wire. During this period, the work content of the crimping

engineer is particularly important. It is necessary to analyze the connector

assembly instructions to find out the connector structure status. Put forward

the development list and requirements to the mold developer to ensure that

there is no problem in the use process after the mold is developed. Through the

above analysis, each crimping method has its own characteristics. As long as a

careful analysis is required, a suitable crimping die can be developed to meet

the crimping requirements and ensure product quality.